Cutting Management System (CMS)

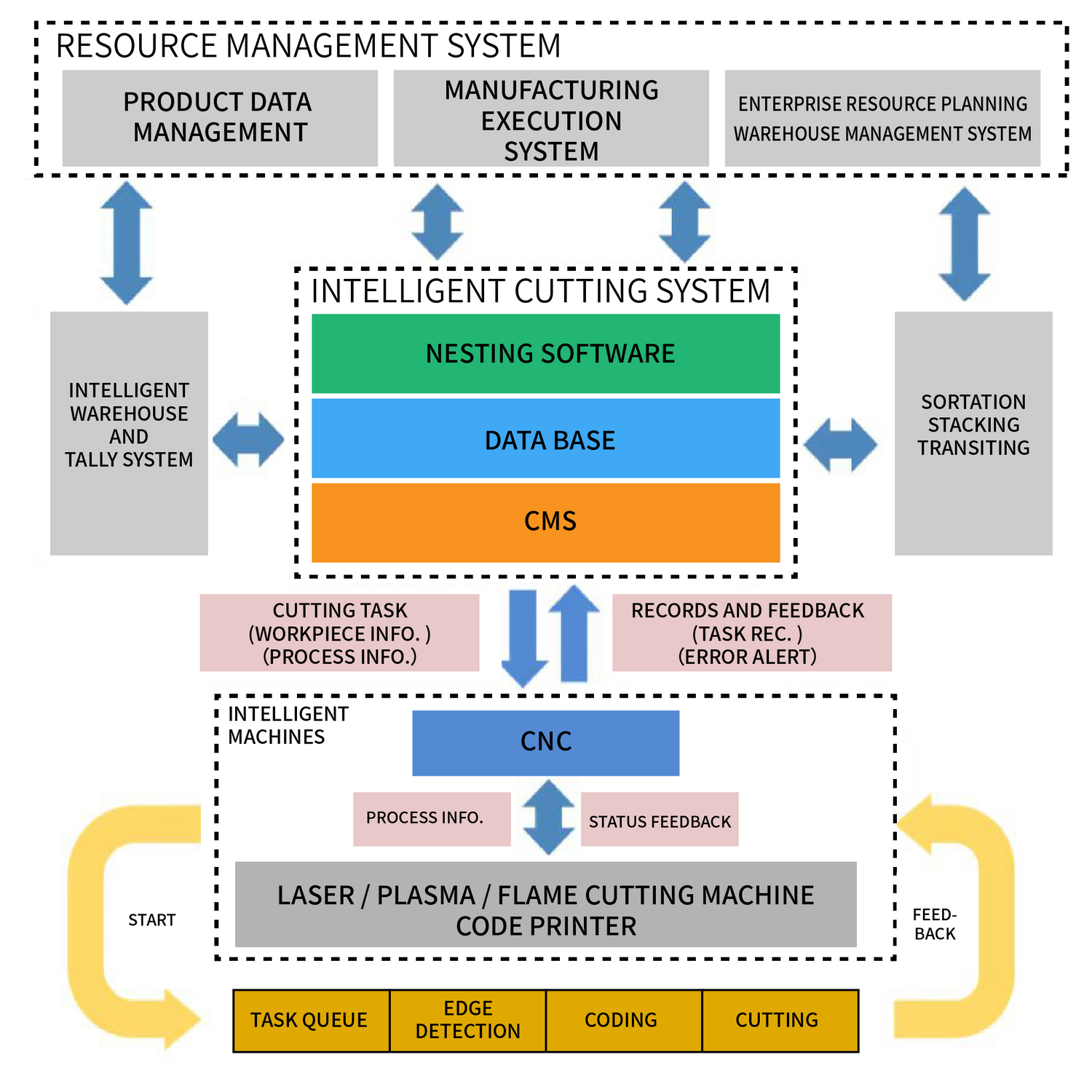

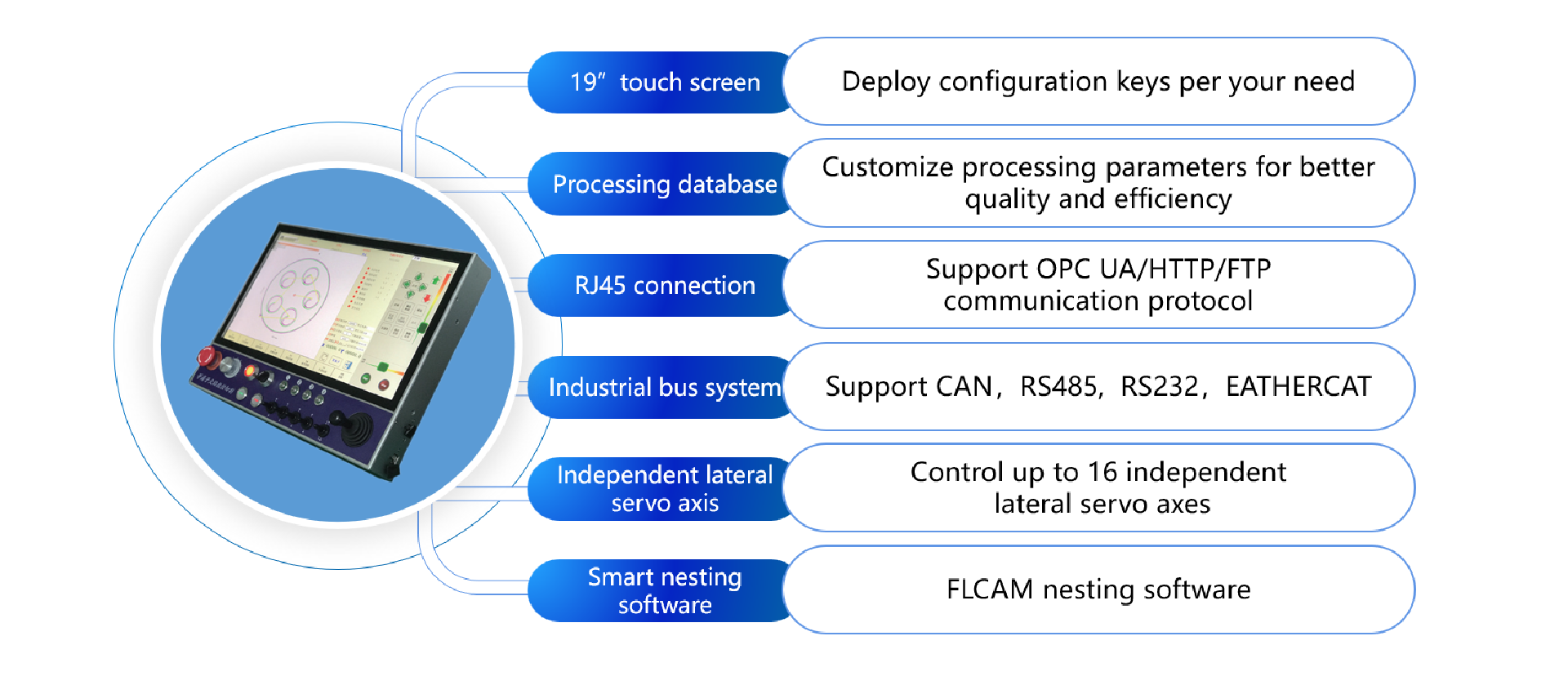

Cutting Management System collects data of production, and realizes automatic control and remote control over cutting process. It is compatible with most mainstream CNC cutting system. Data base could be integrated into ERP or loT network. System could be expanded for other automatic applications, and be integrated into upstream and downstream control system, so as to achieve a fully automatic workshop in the future.

A. What is CMS?

CMS is a system in-between upstream control and management system and downstream cutting equipment. It gives orders to CNC cutting machines, collects data, and feed the data to resource management systems such as MES, or ERP. It can serve as part of a fully automated processing workshop.

B. What can CMS do?

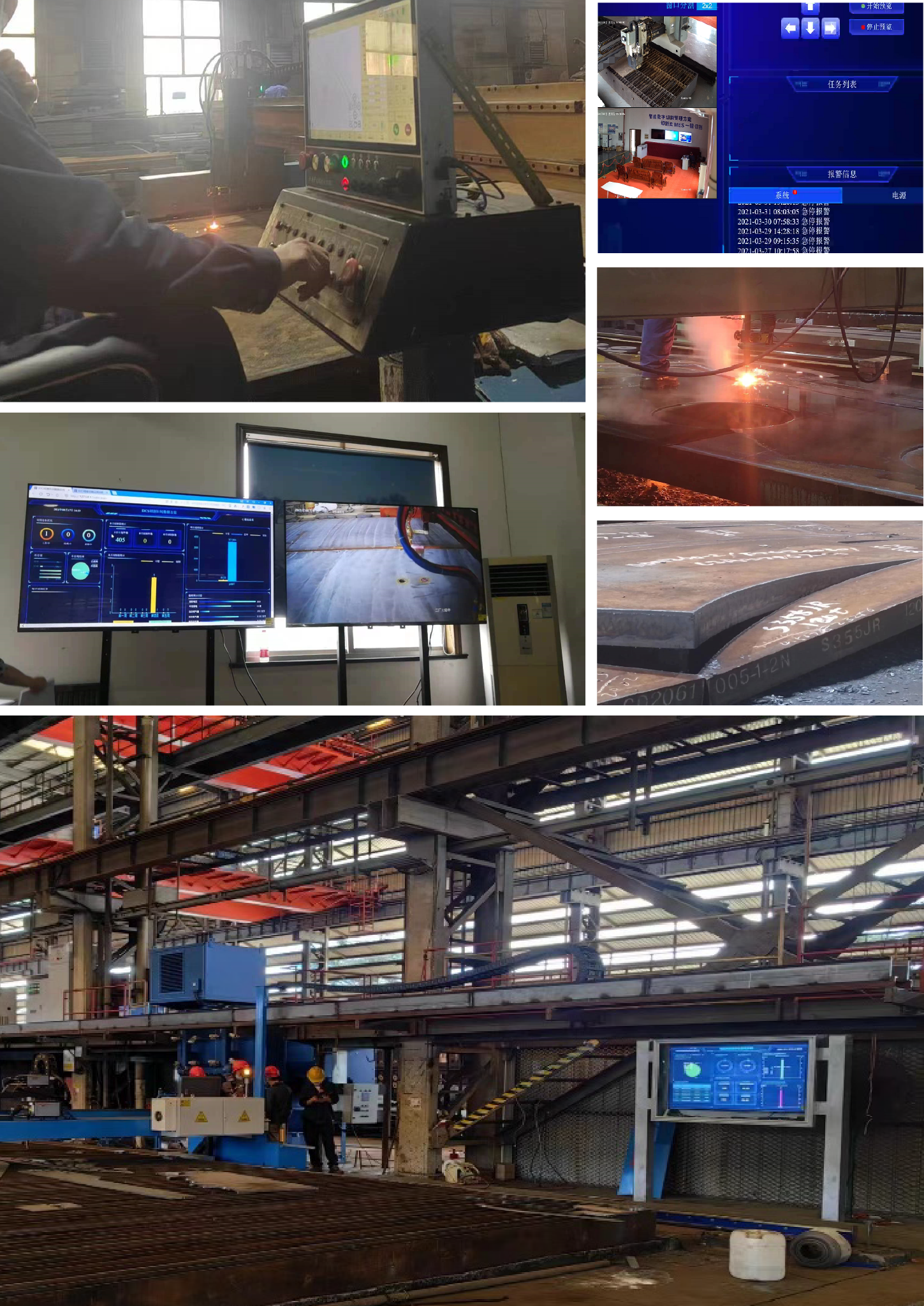

- Remote Control: Sending NC-Code to CNC cutting machine in the workshop, cancelling cutting mission, or monitoring status of cutting equipment remotely from, for example, an upstairs office.

- DATA Storage: Permanent storage of NC-Code for later interrogation and use.

- Alert log: Displaying alarm code and solution sheets and keeping track of alert incidences.

- Management: Status monitoring of multiple cutting equipment; and collecting statistics on set parameter such as individual workload, energy consumption, maintenance records, etc. Real-time data could also be projected to an onsite screen for information display, or to be send to MES, ERP system.

When we are entering into a new era facing shortage of skilled workers, increasing labor cost, a fully automated intelligent processing workshop will be an ideal upgrade for manufacturers. And CMS will serve as a key part of this future production line. But you can try CMS now and start to build up your own intelligent workshop. Please feel free to contact us and learn more about CMS.

KLS, A TRUSTWORTHY PARTNER

Our machines have been serving renowned manufacturers in mainland China in fields such as shipbuilding, steel structure manufacturing, wind turbine and wind tower production, bridge substructure and superstructure construction, pressure container and boiler manufacturing, chemical reactor manufacturing, etc. Updated construction and innovative technology in digitalization, NB-loT application, as well as digital-intelligent automation ensures efficiency and productivity. Contact us if you are interested in our products or in distributing our products.