Application in Wind Power Industry

The current working process to build doorframe of a wind tower includes two procedures of cutting through the tower wall and welding the door frame.

A. Bottleneck Problems

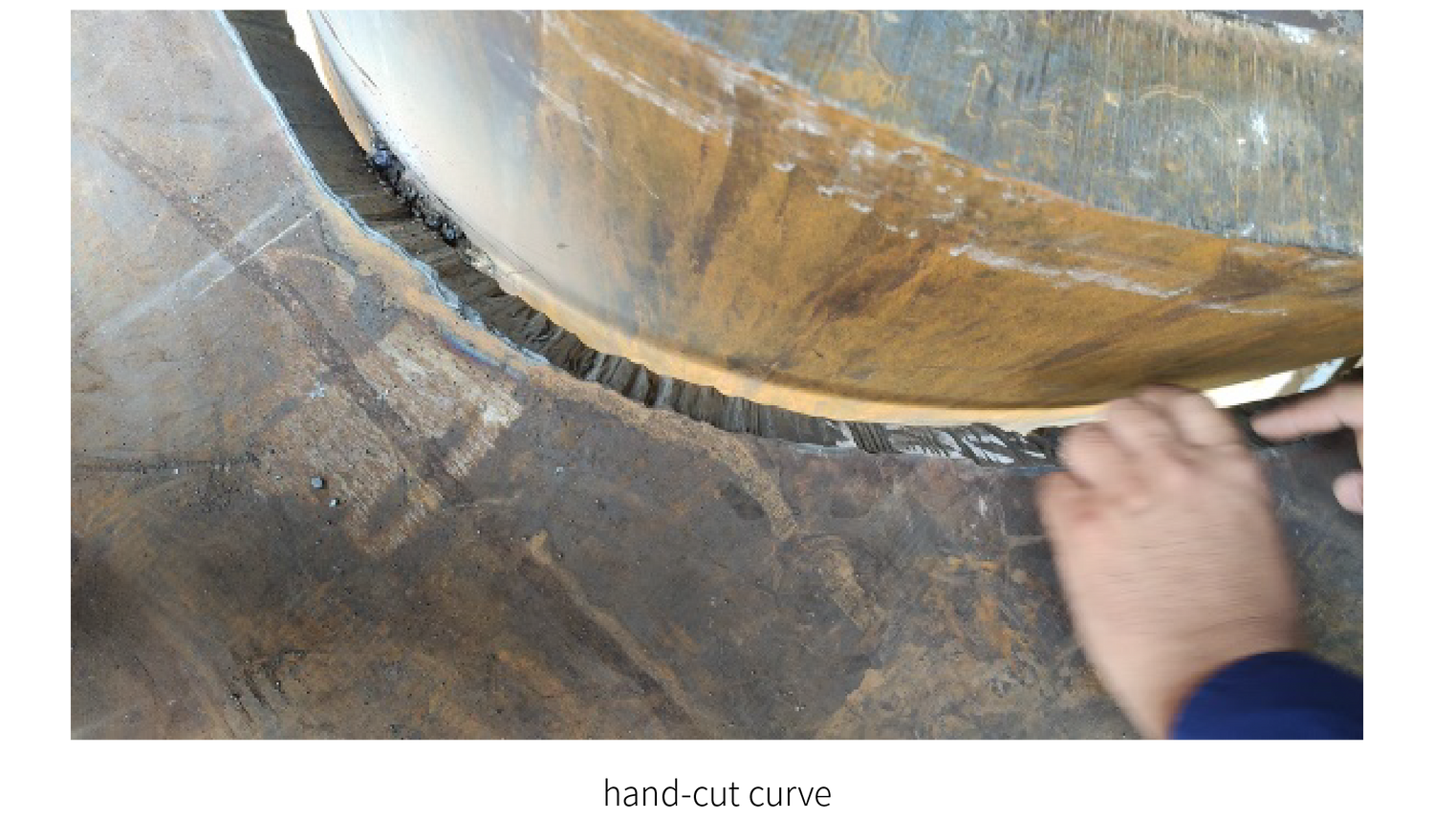

Our client previously employed automatic flame cutting carriage for cutting the straight lines and hand cut the curves.

However, hand cut leaves crude and rough cut-surface, which requires much effort on grinding before welding. And hand-cut lines are not precise, enlarged gap between two workpieces means more labor, and more welding consumables.

Another problem with hand cut is prep time before cutting. To draw the elliptical plan is inconvenient and time costly.

B. Machine-cut vs. Hand-cut

Compared with previous procedure of semi-automatic and hand cut, our beveling machine has laser scan, cutting path simulation, graphic input and display, considerably reducing prep time before cutting.

Top-quality cut-surface, precise and accurate cutting path needs no grinding, saving both labor and time, improving welding quality, boosting productivity.

KLS, A TRUSTWORTHY PARTNER

Our machines have been serving renowned manufacturers in mainland China in fields such as shipbuilding, steel structure manufacturing, wind turbine and wind tower production, bridge substructure and superstructure construction, pressure container and boiler manufacturing, chemical reactor manufacturing, etc. Updated construction and innovative technology in digitalization, NB-loT application, as well as digital-intelligent automation ensures efficiency and productivity. Contact us if you are interested in our products or in distributing our products.