1

/

of

4

KLS Cutting, Welding & Smart Machines

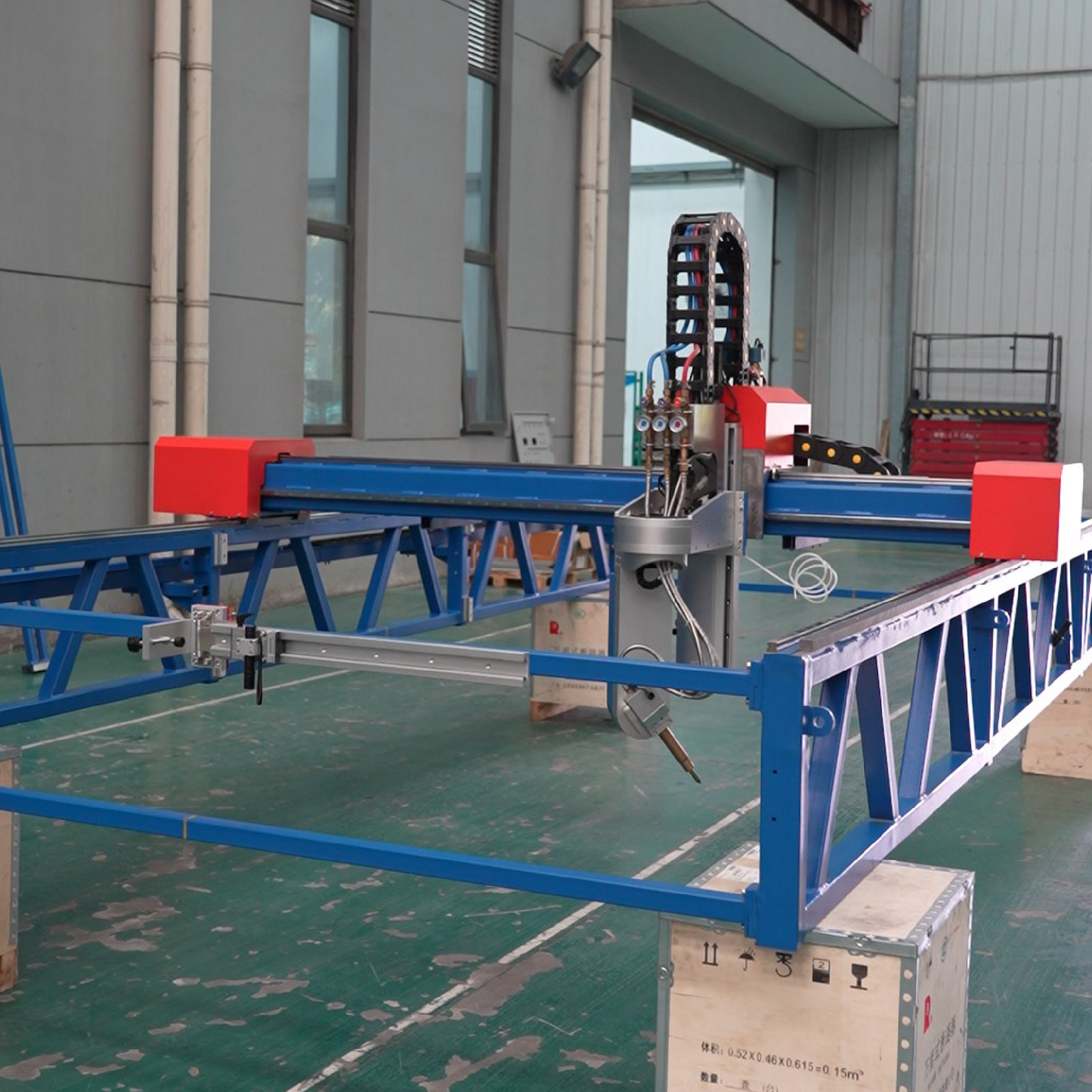

KLS-1535F Portable Cutting and Beveling Machine for Doorframe of Wind Tower

KLS-1535F Portable Cutting and Beveling Machine for Doorframe of Wind Tower

Portable Cutting and Beveling Machine specially designed for cutting and beveling of door and ventilation frame in steel wind tower production, equipped with position scanner and feedback system to ensure top quality, eliminating defects, reducing weld prep time, lowering labor cost, and boosting productivity.

Features

- Control System

- Welding path scan and feedback system

with short setup time and easy-to-read

data display enables accurate outcomes

and one-man operation.

- Built-in network router enables remote

access to control interface.

- Digitalized power and gas consumption

data feedback can be integrated into ERP

system for better management of production

cost.

- Welding path scan and feedback system

- Construction

- Rigid portable frame structure for easy

transportation and sustainable use, and fits

most applications.

- Rigid portable frame structure for easy

- Oxy-fuel Cutting and Beveling torch

Specification

| Cutting Width |

1500mm |

| Cutting Length |

3500mm |

| Height Adjustment Range |

400mm |

| Gas |

Oxygen-Propane |

| Cutting Thickness |

20-100mm |

| Machine Overall Dimension |

2400mm x 4700mm x 1700mm |

* Suitable for door or ventilation frame size up to 1500mm x 3500mm; for applications requiring larger operation dimension, please contact us for more information.

Share