Application in Blanking Process

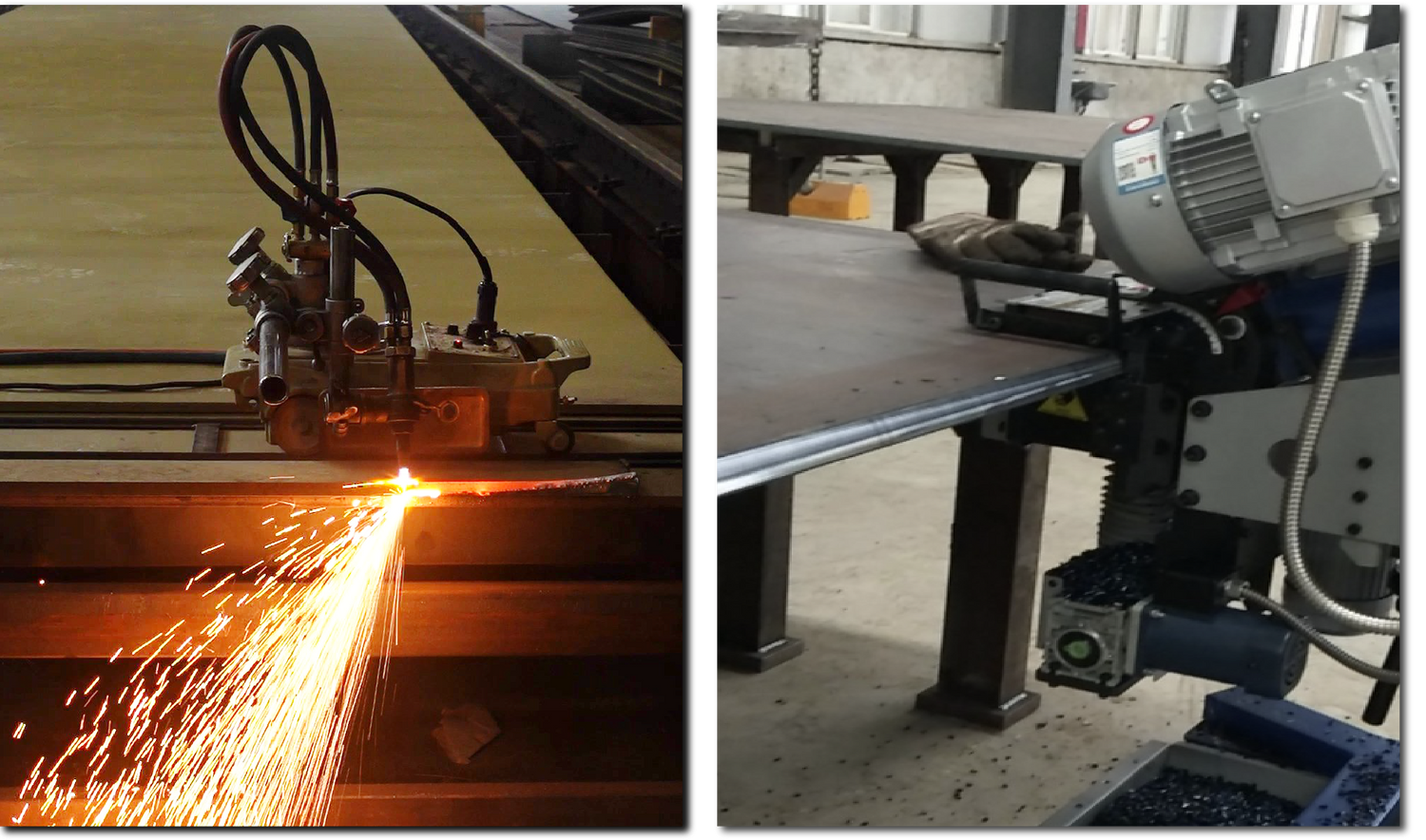

Most blanks workshops use either edge milling machine, or semi-automatic flame cutting carriage for beveling process of thick metal plates.

A. Bottleneck Problems

The bottleneck problem of current procedure is that cutting and beveling are done in different workstations. It requires time and labor to transfer the workpiece and double the space needed for the whole blanking process.

B. Productivity is Crucial

Our beveling machine cuts and bevels. There is no need for transferring the workpiece, saving both time and space. Multiple torch modules might be added to boost productivity even more.

C. Cutting Management System

Cutting Management System (CMS) collects data of production, and realizes automatic control and remote control over cutting process. It is compatible with most mainstream CNC cutting system. Data base could be integrated into ERP or loT network. System could be expanded for other automatic applications, and be integrated into upstream and downstream control system, so as to achieve a fully automatic workshop in the future.

KLS, A TRUSTWORTHY PARTNER

Our machines have been serving renowned manufacturers in mainland China in fields such as shipbuilding, steel structure manufacturing, wind turbine and wind tower production, bridge substructure and superstructure construction, pressure container and boiler manufacturing, chemical reactor manufacturing, etc. Updated construction and innovative technology in digitalization, NB-loT application, as well as digital-intelligent automation ensures efficiency and productivity. Contact us if you are interested in our products or in distributing our products.